Collaborative robots are relatively new in the factory. For over five decades now, traditional industrial robots have dominated the factory floor. They stand proudly in automotive manufacturing industries and many other factories that produce large and heavy items.

With the popularity and increased uptake of collaborative robots, there has been debate on which is better. Each of these robots has their strength and weaknesses. They also have areas in which each are suitable.

Here are scenarios and glaring differences between the traditional industrial robots and the contemporary collaborative robots.

Initial acquisition costs

Traditional industrial robots are quite expensive to acquire. They are large and therefore require a large space to work in.

Therefore, they are quite out of reach for a small manufacturer with a small manufacturing space and limited funds. But, it is all about what you need, and Universal-Robots can help you pick the right one for your company.

Collaborative robots are quite affordable. They are price levels are within reach even for a small manufacturer. Further, you do not need much preparation to receive the robot.

So, for example, if you want to go with cobot, as it’s called, you are in for a robot that is easy to integrate and intended to replace the human workforce in tasks that are deemed dangerous or are simply too repetitive. When thy are what you need, then the human workforce is there to deal with manual functions that hold a higher value. As we said, they are cheaper than standard industrial robots, especially when you are looking at the upfront price. It is thanks to the smaller price that small companies managed to get their hands on them. This is can even be considered as a small win in a big technological revolution which is happening right now and will continue in the future. But, this doesn’t mean all small businesses should reach for them straight away, just because they’re accessible.

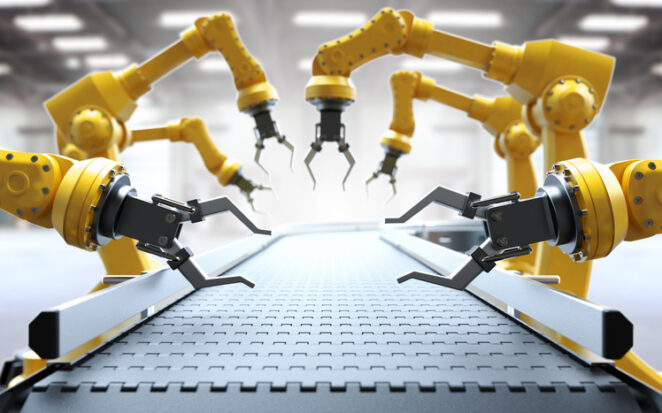

On the other side, we have industrial robots. There are many models, and even if you are a little bit into this subject, you probably heard about 6-axis, cartesian, or SCARA models. Here we are talking about massive machines able to take on almost all dangerous, repetitive, and heavy duties. You’ll find them in gigantic factories that assemble parts of large vehicles, for example or pick and place. Industries have been using them for decades for palletization and similar tasks.

These robots are more expensive at the start, but they’re also on a completely different level. Payload and speed can’t be compared to cobots. The reason is simple – cobots are tied to a simple rule: the more significant the load, the less speed they generate. Furthermore, there are tectonic shifting in this industry, and today we have more and more industrial robots coming at fair and affordable prices. This is why more small businesses are looking to bring them in. It also makes financial sense. With industrial robots, you get a better return on investment. These robots come at a higher price, but ROI is increased because of faster performance, which generates more work in less time.

Ease of use

Collaborative robots are much easier to use compared to traditional robots. First, they do not require a specialized robot programmer that are expensive to employ. With a little training, any factory employee can operate a cobot. They can also be physically trained on how to carry out different tasks in the factory.

To automate with traditional robots, companies need to hire a specialized robot programmer who will code instructions to the robot on how to carry out assigned tasks.

Size

There is a significant difference in the size of these two types of robots. The traditional robot is large and requires a significant amount of space to fit and to work in. The manufacturer, therefore, has to have large enough factory floor space to use it.

Collaborative robots are much smaller. Further, they are mobile. They can therefore work in different parts of the factory. Traditional robots are largely immobile and work has to be taken to them.

Type of tasks they handle

There is a stark difference between the type of work these two robots can handle in a factory.

Where you have heavy and large objects to lift and work on, the traditional robot is the most suitable. Also, they work much faster than collaborative robots even when dealing with large materials. So, for tasks that require speed, the traditional robot is your best bet.

The collaborative robot is best suited for tasks that help move human workers from repetitive tasks. Tasks such as pick and place tasks, quality inspections, painting and welding.

Safety

This is another area with a significant difference between the two types of robots.

Collaborative robots are significantly safer than traditional robots. This starts with their design. They have smooth and rounded edges to ensure that no one is injured from accidentally bumping into the robot at the factory.

Also, cobots have internal sensors that can sense the presence of human beings close to them as they work. As a result, they will slow down and even shut down when touched.

Traditional robots have lower safety levels. Factory workers are not allowed to get close to them when they are working, they have to be shut down. To maintain safety, these robots are fenced off an only authorized persons can get anywhere near them. However, there have been many fatal cases that arise from accidents with these robots.

Human presence replacement in the factory

Traditional robots eliminated human presence in their part of production. This led to loss of jobs that were previously carried out by human. However, it increased the speed with which production was carried out and improved quality.

Cobots, work easily alongside human workers. They take over repetitive and ergonomically unsuitable tasks to humans, and let the human workers focus on other higher-level tasks. They even lead to increased employment.

Conclusion

Different companies have different automation needs. These needs could be well suited for either the cobots or traditional industrial robots. With these differences, you are in a better place to decide what type of robot you need. The answer might not come easy as there would be many questions to answer before deciding whether an industrial robot or cobot is best suited for your business. It all comes down to space you have, the required level of automation, and the primary focus and niche of your company. All that we can hope is that the article above helped even a little bit with your decision.

Vermont Republic Second Vermont Republic

Vermont Republic Second Vermont Republic