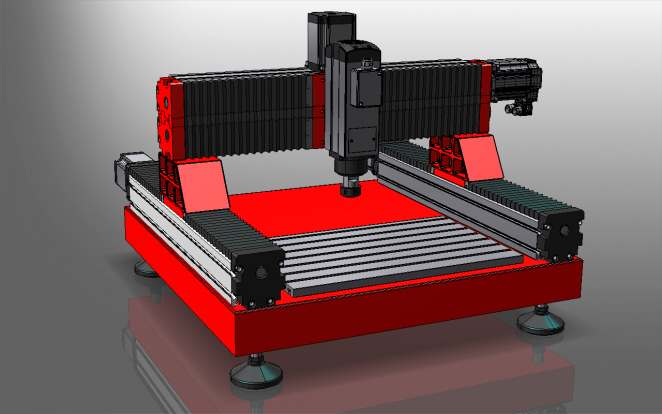

If you have started your own small business or if you are looking to upgrade your machinery, a CNC machine is probably one of the first things you are planning to invest it. The problem with such an investment is the fact that this is not a cheap or simple investment. When paying for a CNC machine, you should expect something that will last for years and that it will provide you with high-quality products. Anything else should not be accepted.

However, choosing the right machine is not as easy as you thought. You have to consider a lot of different factors and whether you will be able to afford it. There are some other things you should consider such as the products you are aiming to produce and the level of quality you want to achieve.

So, before you start looking for a CNC machine, the first thing you will need to do is properly understand your products and their requirements. Once you understand what you should do and the materials you will use.

To help you make the right decision and invest your money in the right place, we are going to help you choose the best CNC machine for your business.

How much does it cost?

The cost of these machines can vary a lot depending on your products and the type of work you are planning to use it for. You might think that most of them do the same thing and that they all look the same, but they are actually very different in pricing. This is why it is so important to do your research first because you might end up with something that is overpriced.

For example, the smallest ones that do the most basic tasks will cost you anywhere between ten and thirty thousand dollars while the largest ones may cost you well over half a million. Depending on the type of business you are running and your needs, you can decide what kind of equipment you really need.

Keep in mind, these prices may vary by location and you may even find them cheaper if you look through second-hand markets.

What type of materials you will be cutting?

Another thing you should factor in when making this kind of investment is what kind of materials you plan on cutting. Of course, you probably have a good idea about the use of this apparatus you are planning to buy, but it is still better to ensure that you know about all of the details regarding it. With CNC you will be able to cut through most metals such as steel, copper, brass, aluminum, etc. You probably already know that you can also cut through plastics, wood, and foam. You can find more information on https://www.krywolt.com/business-insurance/.

Research brands

Naturally, in every industry, there are certain brands that deliver the most reliable and the highest quality of products. Assuming that you want to invest in something that provides you with high-quality products and something that is durable, then you will definitely need to go through an in-depth analysis of every brand that creates CNC machines. If you are looking for a brand that always provides a high-quality product, you should check out elephant CNC.

Consider the space

CNC machines are an expensive investment, heavy and a commitment that you can’t just look through it. You will need to dedicate a lot of your time and willpower to ensure that it will work properly and that it is optimized for the best possible results. This is why many manufacturers of these devices inform you to consider the SWaP limits of your factory or offices. Basically, SWaP is an acronym that reminds you not to forget about the requirements of space, weight, and power.

- Space

You might feel like your offices or workshop is big enough to install any kind of machinery you buy, but you shouldn’t make any decision before properly measuring your space and the item you plan on buying. It is always better to be safe than sorry, right? So, logically, if you do not have enough space for the CNC of your dreams, you should definitely look for something smaller that can meet your requirements.

- Weight

A properly constructed building, you will probably never have a problem with the weight of any kind of machine. However, better safe than sorry, right? You do not want to spend several hundred thousand dollars on something that may get destroyed because the floor of your workshop couldn’t handle its weight.

- Power

We cannot ignore the fact that CNC devices are very power-hungry, especially if you are planning on buying on 4-axis or a 5-axis one. You will need to ensure that your work has an output of 220 volts available, otherwise, you might cause more damage to it. Keep in mind, most of the smaller CNC devices can work on 110-volt power easily.

Replacement parts

Many business owners consider the idea of second-hand CNC machines and that is completely fine. In fact, it actually might be a better investment to buy a second-hand one than wasting so much money on a brand new one.

However, it is no secret that when you are buying an old product, there is a chance of it breaking down. In these moments, you will probably need to look for replacement parts so you can continue your work. The worst part about these kinds of situations is the fact that some second-hand CNC devices are so rare that you can’t even find a reliable source of spare parts. Even if you do find a place where you can buy them, their prices are too high.

Make sure it works

Naturally, if you plan on buying a second-hand product, you should make sure that it works properly. This doesn’t mean that you should plug it in and press start once. Before you make the purchase, you should let it run through a couple of commands for a couple of minutes and ensure that it still works like its prime days.

Vermont Republic Second Vermont Republic

Vermont Republic Second Vermont Republic