After decades of dominance, globalization opened North American manufacturing up to competition from countries with historically smaller economies that benefitted from cheaper labor costs and fewer regulations. Factories around the continent managed to fight back by increasing automation on assembly lines, which made their operations more efficient and cost-effective.

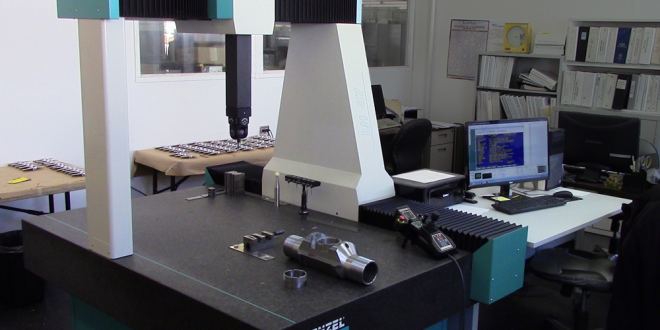

One of the tools that made automation possible is the coordinate measuring machine or CMM. CMM machines are relied upon to perform quality control on the assembly line — they scan parts ranging in size from micrometers to over a hundred feet with incredible precision, and can tell if they have a defect. Because they can be operated by a human or by computer, they lend themselves perfectly to performing quality control.

Your CMM machine can do wonders for your company, especially if you take the best care of it possible. Here are some tips that will help it to deliver the best result possible.

Proper Installation

You need to be certain that your CMM machine works perfectly from the get-go, and for that, it needs to be installed by an experienced metrologist. They are sensitive pieces of equipment, and even things like the room temperature can impact its performance if it’s not properly taken into account from the time of installation.

To ensure your CMM machine works perfectly you need to consult authorized dealers, who in addition to selling CMM machines service them too. Visit an authorized CMM dealer for portable arm recalibration, upgrades and retrofits, CMM calibration, machine relocation, and also preventative maintenance. You should be sure to read this because recalibration is vital throughout the life of your machine, and it’s important to know all you can about it.

Expert Service Only

Does your company have an in-house metrology expert? If not, you can hire one to consult about things like sourcing replacements parts and machine calibration. These are complex machines and they have in-depth knowledge about every kind, as well as all the parts like probes, probe heads, and all the newest software.

Don’t trust an expert unless they are ISO 9000 and ISO 17025 accredited.

Keep Your Employees in the Know

You can get your CMM machines to deliver better performances by ensuring that the people who operate them have up to date knowledge.

To get the best CMM lessons, consult a measurement solutions provider — in addition to selling and servicing the equipment, they offer CMM training and e-courses too. It may seem counterintuitive that the machines associated with automation require human employees to work, but not every aspect of a CMM machine is automated.

E-Learning permits students to learn without having to even leave the factory where they’re already working, and lets them take lessons at their own pace. These courses can serve as a refresher for employees who have already undergone sufficient training, as there’s a library of software features all employees can brush upon.

CMM machines can give your operations a vital boost by making your assembly line more efficient, which is necessary because the competition doesn’t appear to be lessening any time soon. But be sure to use all of the above tips, so that yours gives you the best performance possible.

Vermont Republic Second Vermont Republic

Vermont Republic Second Vermont Republic